Material Superiority

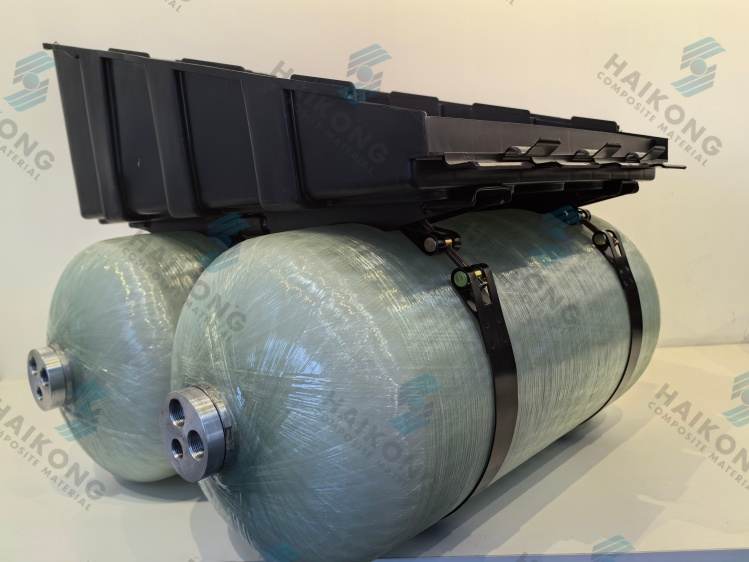

Type IV cylinders with thermoplastic liners (e.g., HDPE/PA6) and full carbon fiber winding exhibit 40%+ weight reduction compared to Type III, along with hydrogen embrittlement resistance and corrosion immunity. These properties align with brake reservoir demands for lightweighting and high-pressure durability (typically ≤1.2MPa).Pressure Adaptation

While designed for 30-70MPa hydrogen storage, their fatigue performance under low-pressure cycling (45000+ cycles in hydrogen tests) may surpass traditional metal reservoirs.

Implementation Challenges

Standardization Gap: Existing certifications (e.g., GB/T 35544) target hydrogen storage, requiring new safety protocols for compressed air.

Potential Applications

Heavy-Duty Trucks: Weight reduction enhances payload capacity.

Corrosive Environments: Plastic liners resist chemical degradation in marine/industrial vehicles.

Shandong Chanyan Haikong Composite Material Co.,Ltd

Add: No. 2877 Shengfu Road, Shengjing Street, Zhangqiu District, Jinan, Shandong, China

Tel: +86 133 2512 6331(whatsapp)

Email: sales@hkfhcl.com

Website: www.hkfhcl.com